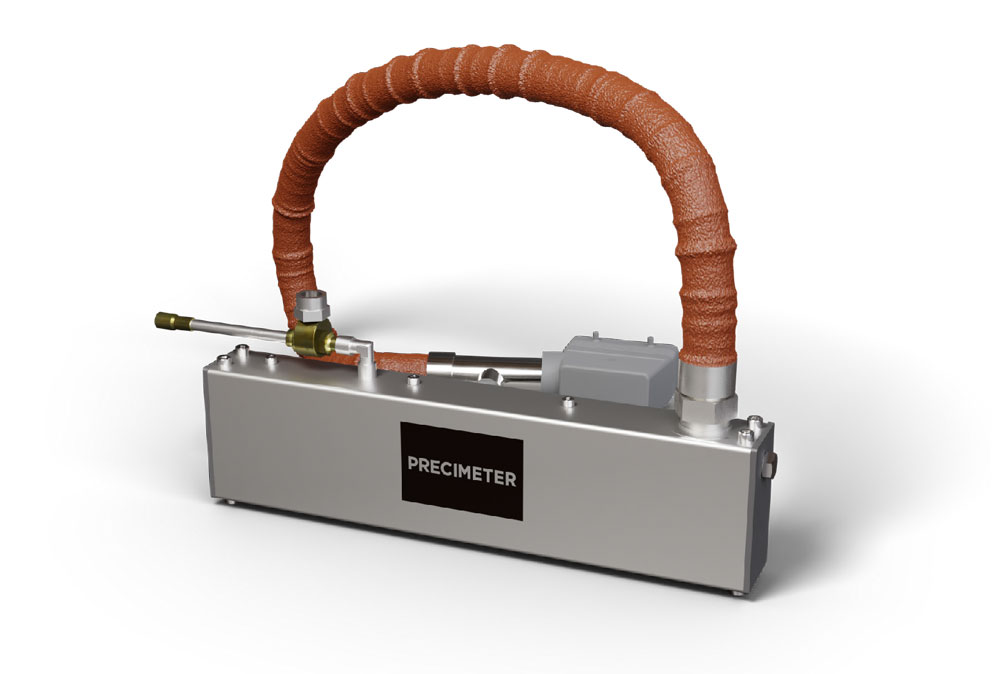

Laser Camera Sensor

The intelligent digital laser and camera metal level sensor family from Precimeter is a high performance laser triangulation device developed specifically for its purpose. It will measure on any molten metal surface with a surface temperature below 1000˚C.

Product information

The Laser Camera Sensor model ProH from Precimeter combines high performance laser triangulation with the necessary control functions to maintain an accurate molten metal level measurement.

The patented digital camera technology in the Precimeter sensors results in very high performance and resolution. The advanced technology enables stable readings even when the molten metal material reflectivity changes dramatically and/or in harsh conditions with heavy steam and smoke environment. The built in PI controller eliminates the need for an external industrial controller.