Historically the use of metallic heatsinks has remained the preferred option for dissipating heat from both mechanical and electronic sub-assemblies. The frequent additional requirement for electrical insulators between such metallic heatsinks and the adjoining surfaces brings with it additional assembly time and cost. Poor surface conformities result in increased, and unpredictable, resistance to heat transfer.

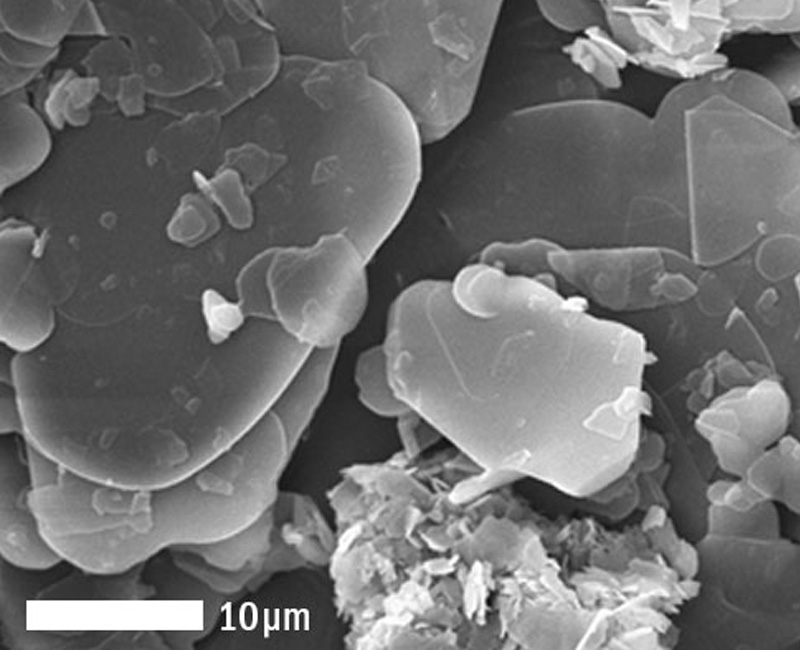

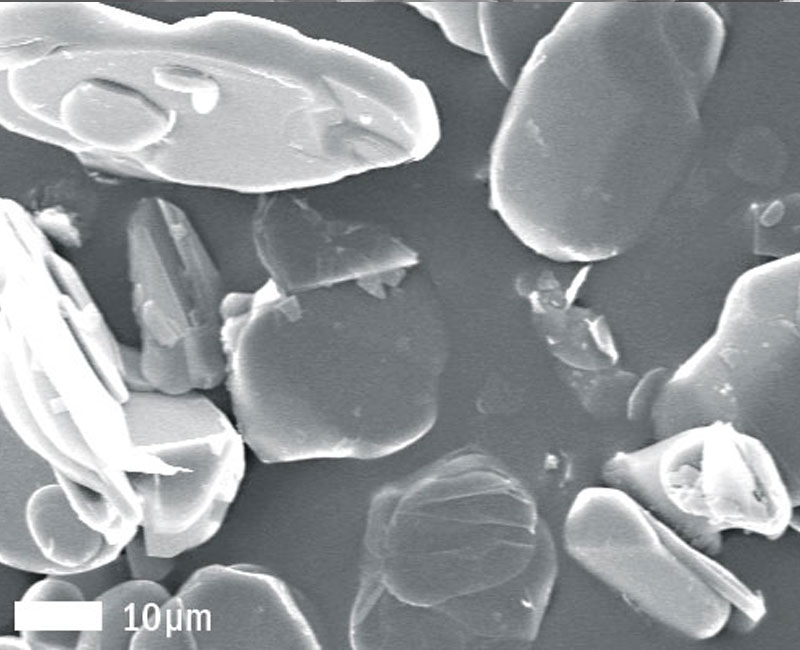

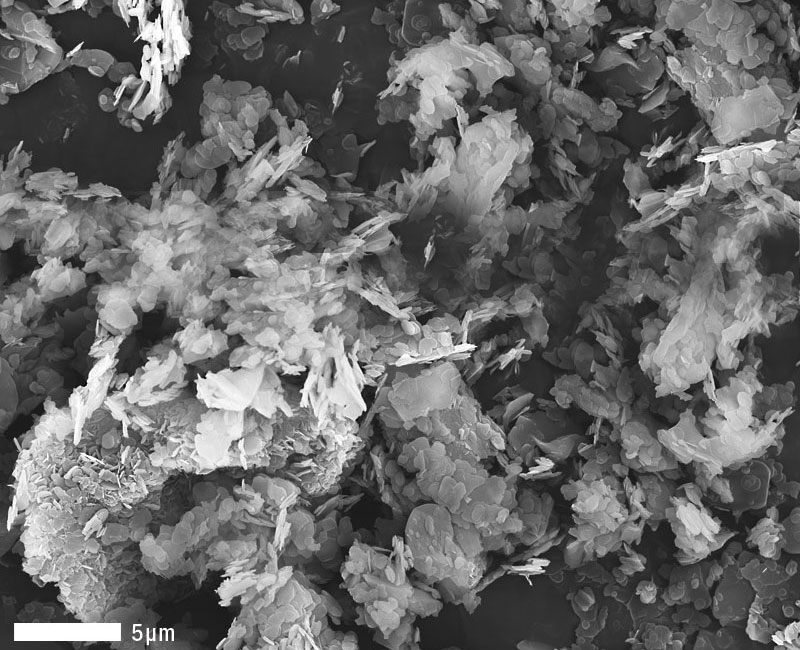

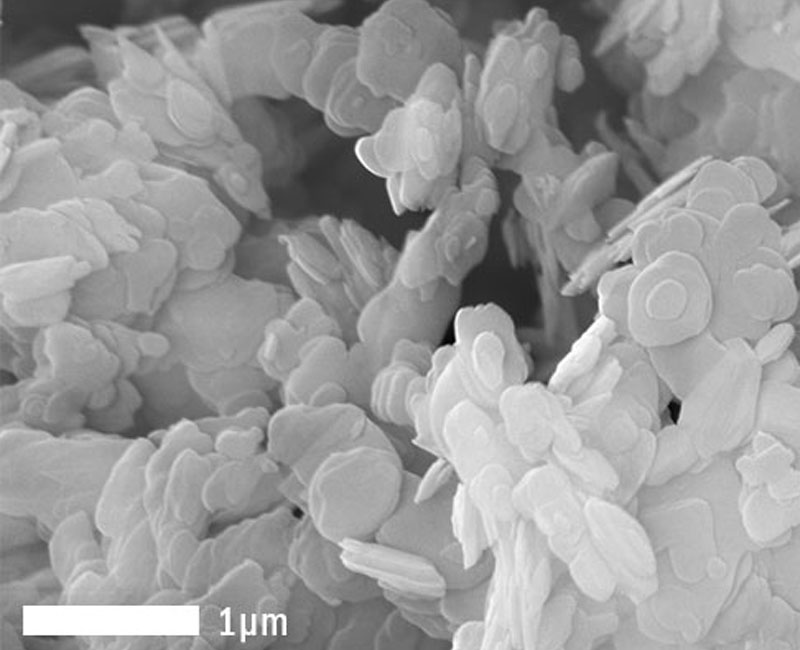

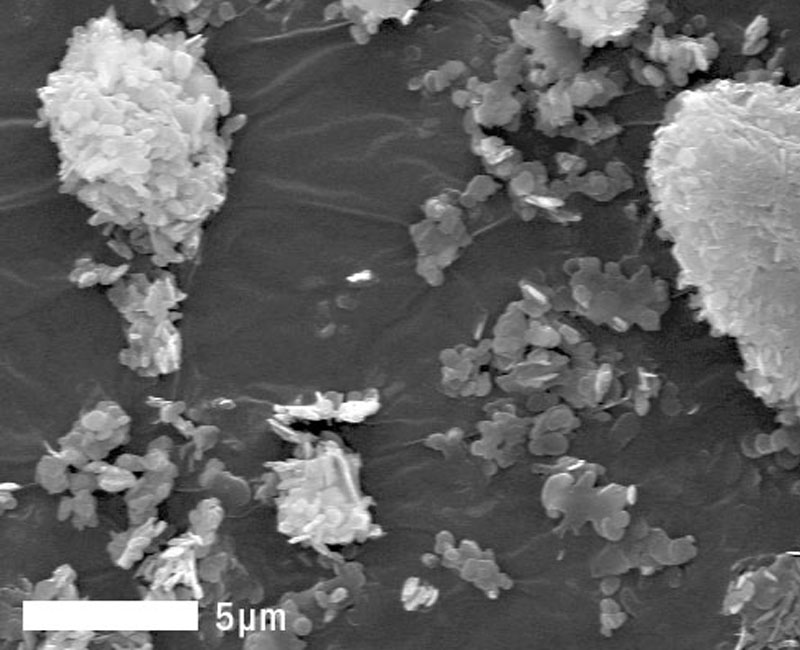

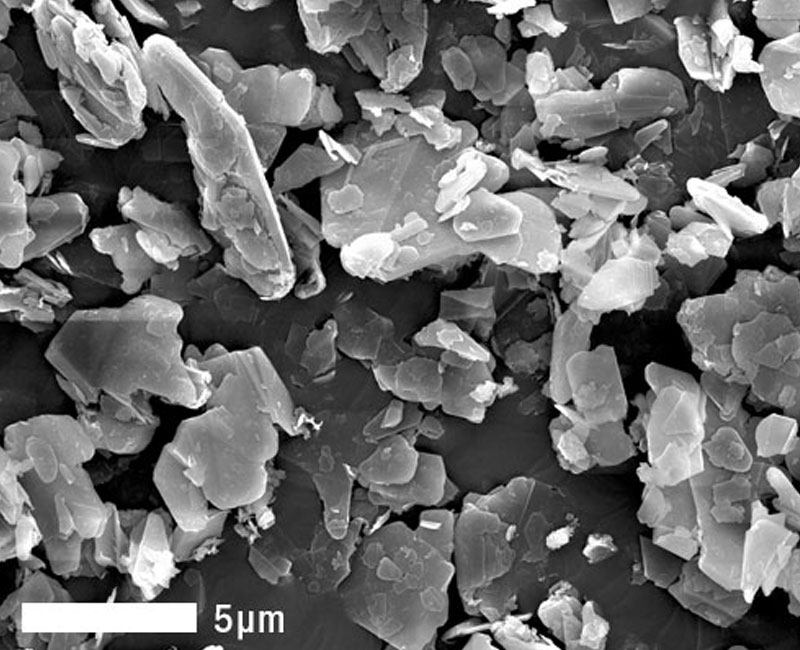

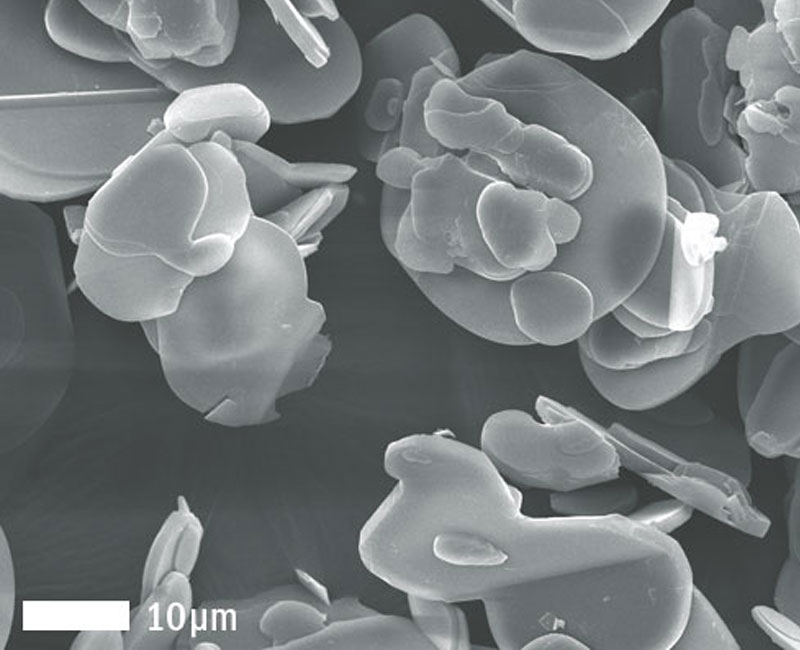

Electrical insulators in the form of thermally conducting polymers represent an innovative alternative for this sector. Henze's HeBoFill® CL-ADM 020, HeBoFill® CL-SP 035 and HeBoFill® CL-SP 045 boron nitride powder have been optimised for use in polymer engineering. They capitalise on the unique properties of boron nitride, which include high thermal conductivity as well as being electrically insulating. An additional advantage that can be gained from incorporating HeBoFill® powder within the polymer substrate is the reduction in wear that arises from reduced friction. Such polymer compounds are therefore well suited for use in polymer bearings and other power-train components.

As a result, both the performance and application spectrum of the basis polymers can be usefully extended through the use of boron nitride powder. Mechanical and electronic components can be directly surface mounted and encapsulated. Heat dissipation from encapsulated components has been found to be significantly improved. Surface conformity and heat transfer are improved. The reliability of electrical insulation with respect to surrounding components is optimised, and functional parts are effectively protected from vibration, and the ingress of dirt and moisture.

Henze BNP HeBoFill® boron nitride fillers represent a broad range of products specifically for use in polymer engineering. Depending on your needs, we may also be able to offer bespoke solutions for your specific application requirements.