During the extrusion pressing process, aluminium billets are converted under high pressure at temperatures in the region of 450 °C into a variety of profiles. Such operating temperatures present unique challenges, in particular the tendency of aluminium to adhere to the press block as well as other working surfaces. In addition, most release agents and lubricants decompose under such conditions, reducing their effectiveness. By substituting Henze products in place of the traditionally used lubricants it is possible to eliminate the surface defects which would otherwise arise.

The result is an optimised release and lubricating performance, also at high temperatures.

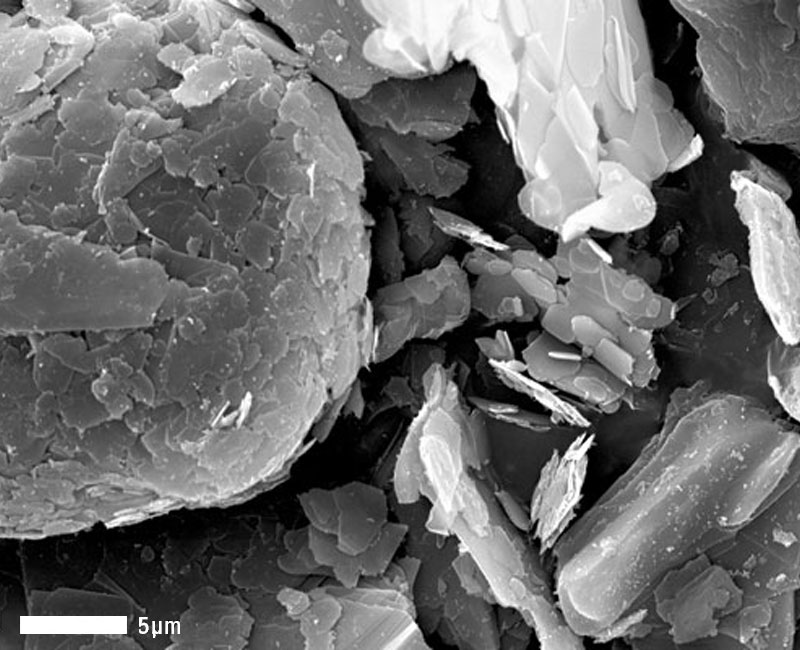

Electrostatically charged HeBoFill® boron nitride can be sprayed as a dry powder, and can be easily incorporated into existing production processes. HeBoCoat® boron nitride liquid suspensions can also be supplied for certain applications.

Henze boron nitride products are particularly suitable for:

- lubricating and coating of press dummy blocks

- coating of running die and tool surfaces

- lubrication of press shears

- lubrication of container seals