The casting of metals, both in pure and alloyed forms, involves the transfer of molten metals into pre-prepared die forms. The process conditions must be optimised in terms of several factors, which include temperature, alloying constituents and component geometry – thus ensuring process consistency, productivity and efficiency.

Boron Nitride provides an ideal solution, both in the form of sintered components or when applied in liquid form to provide a Boron Nitride surface coating. The high release properties of Boron Nitride prevent the melt and its oxides from adhering to the surface. As a result, it is possible to increase the efficiency of the casting process.

Our HeBoCoat® products provide a wide range of water-based suspensions which ideally lend themselves as coatings for refractories and ceramic components such as runners, nozzles, stoppers or thermocouple protection tubes. It is also possible to provide similar coatings for casting and ingot moulds, ladles, and other tools.

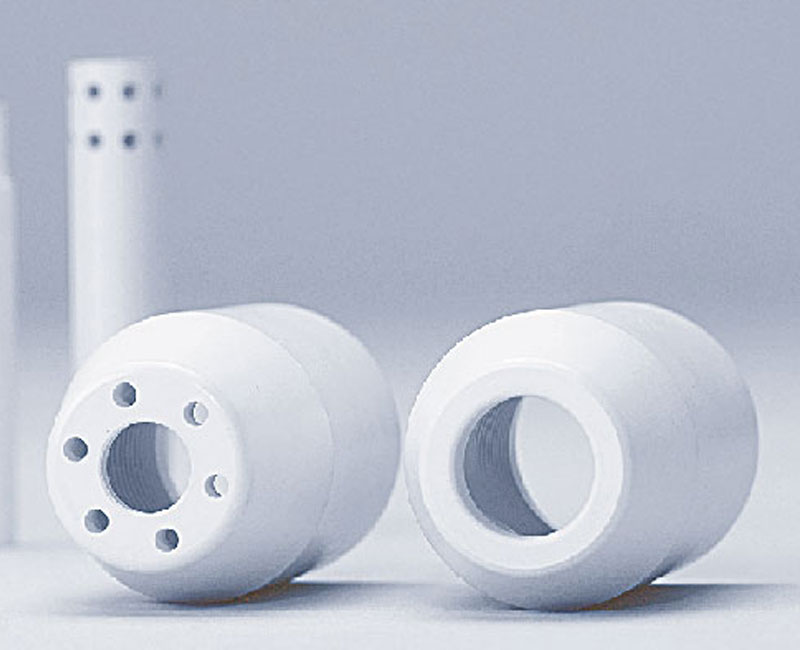

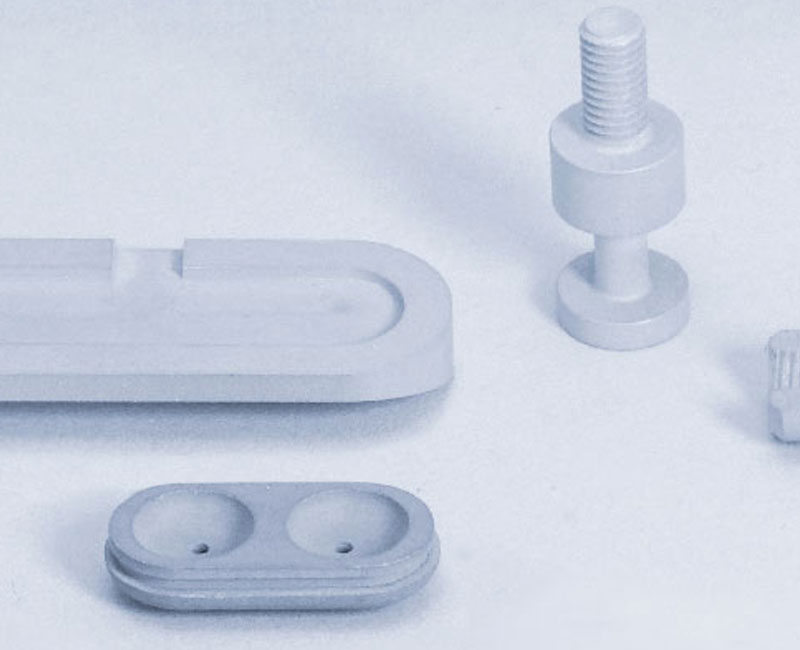

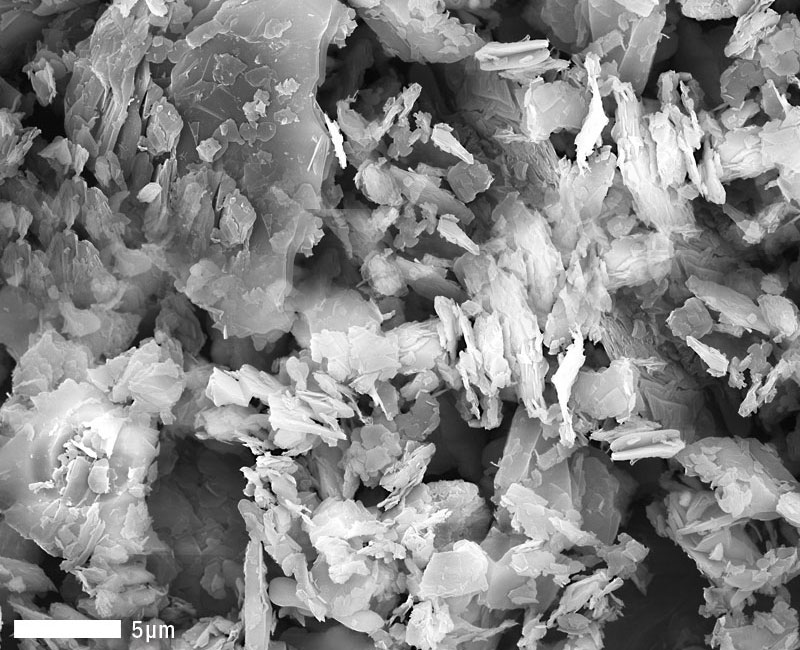

Boron Nitride sintered components are also extensively used in metal casting processes, typical examples being nozzles, rings, crucibles and moulds. They offer excellent temperature resistance, good thermal shock resistance, good thermal conductivity and high mechanical strength. Our HeBoSint® STRONG LINE product range has, due to its exceptional material properties, proved itself in such applications. Due to its good machinability it is possible to manufacture geometrically complex HeBoSint® STRONG LINE components to tight tolerances – tailored precisely to customer requirements.